4 JAW / 3 JAW Lathe Chucks

Lathe chucks are equipment that it's in Headstock. Lathe chucks use for holding the lathe.And,there are 3 types.

1.Lathe chucks three-JAW Self centering - It can handle hex bar-stock.

2.Lathe chucks four-JAW Independent lathe - It can handle square/rectangular bar.

3.Lathe chucks four-JAW Self centering - It can handle square/rectangular bar.

TRICK : Compare of three-Jaw VS four-JAW

| three-Jaw | four-JAW | |

| Chuck can be centered to high precision | : NO | YES |

| Chuck can handle square | : NO | YES |

| Chuck can handle hex bar-stock | : YES | NO |

| Chuck can turn off-center | : NO | YES |

TRICK : Compare of Self centering VS Independent lathe

| Independent lathe | Self centering | |

| Save time and easy to use | : NO | YES |

| Chuck Can hold irregularly shaped work | : YES | NO |

| Chuck can be centered to high precision | : NO | YES |

TRICK : How to know what are jaws of Lathe chucks.

Jaw are in front of chucks as above picture.and,it have 4-Jaw.So that it's call 4-JAW Chucks

|

Lathe Chucks three-JAW Self centering |

Lathe Chucks Four-JAW Self centering |

Lathe Chucks four-JAW Independent |

|||||

|

SIZE |

2" |

SIZE |

3" |

SIZE |

6" |

||

|

3" |

4" |

8" |

|||||

|

4" |

5" |

10" |

|||||

|

5" |

6" |

12" |

|||||

|

6" |

8" |

14" |

|||||

|

8" |

10" |

16" |

|||||

|

9" |

20" |

||||||

|

10" |

24" |

||||||

|

12" 15" |

|||||||

How to hold workpieces with 3 chucks

1. Use a wrench to tighten the chuck. Loosen the mouth of the 3 chucks and turn it counterclockwise. Jaw of the chuck is wider than the workpiece

2. After that, bring the workpiece into the slot. Jaw of the chuck By keeping the end of the workpiece away from the mouth of the chuck moderately.

3. Turn the wrench clockwise until the jaws hold the workpiece firmly. and then remove the wrench from the chuck

How to attach a lathe chuck to the pivot shaft on the pedestal head.

Usually, the head of the lathe It will be on the left side of the engine base (BED). It is the part that is used to hold the lathe chuck,face plate,collet chuck.

In order to turn the workpiece by means of fixing the lathe chuck to the shaft, there are 2 types as follows.

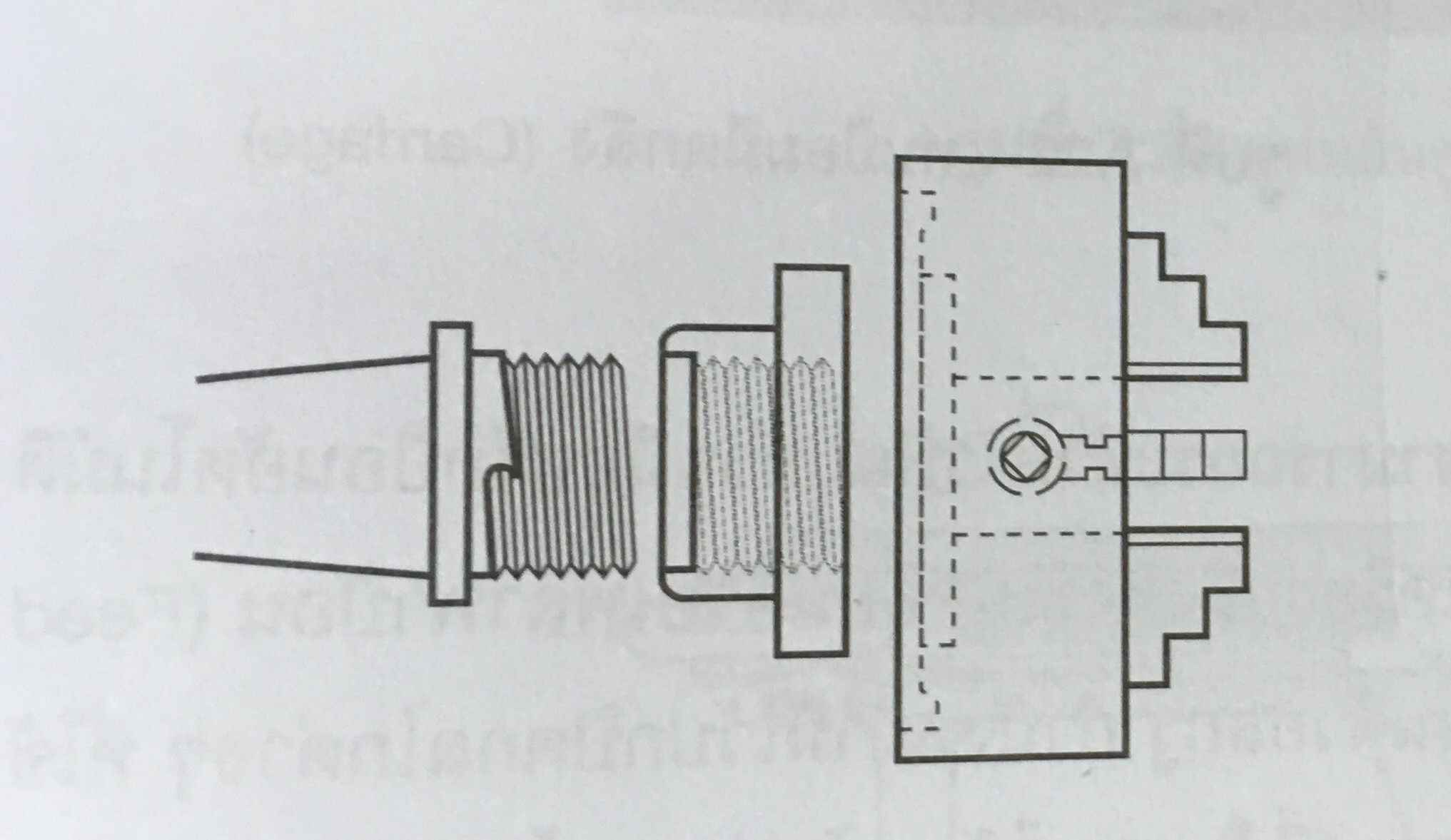

1. Screw type

2. Splice plate type which after the chuck is attached to the lathe The spindle of the shaft is driven to rotate by the motor. Through a system of gears or weaves mounted under the head of the platform for changing the speed of the lathe must always stop the machine first, except for special lathes that can adjust the speed continuously while the machine is running.

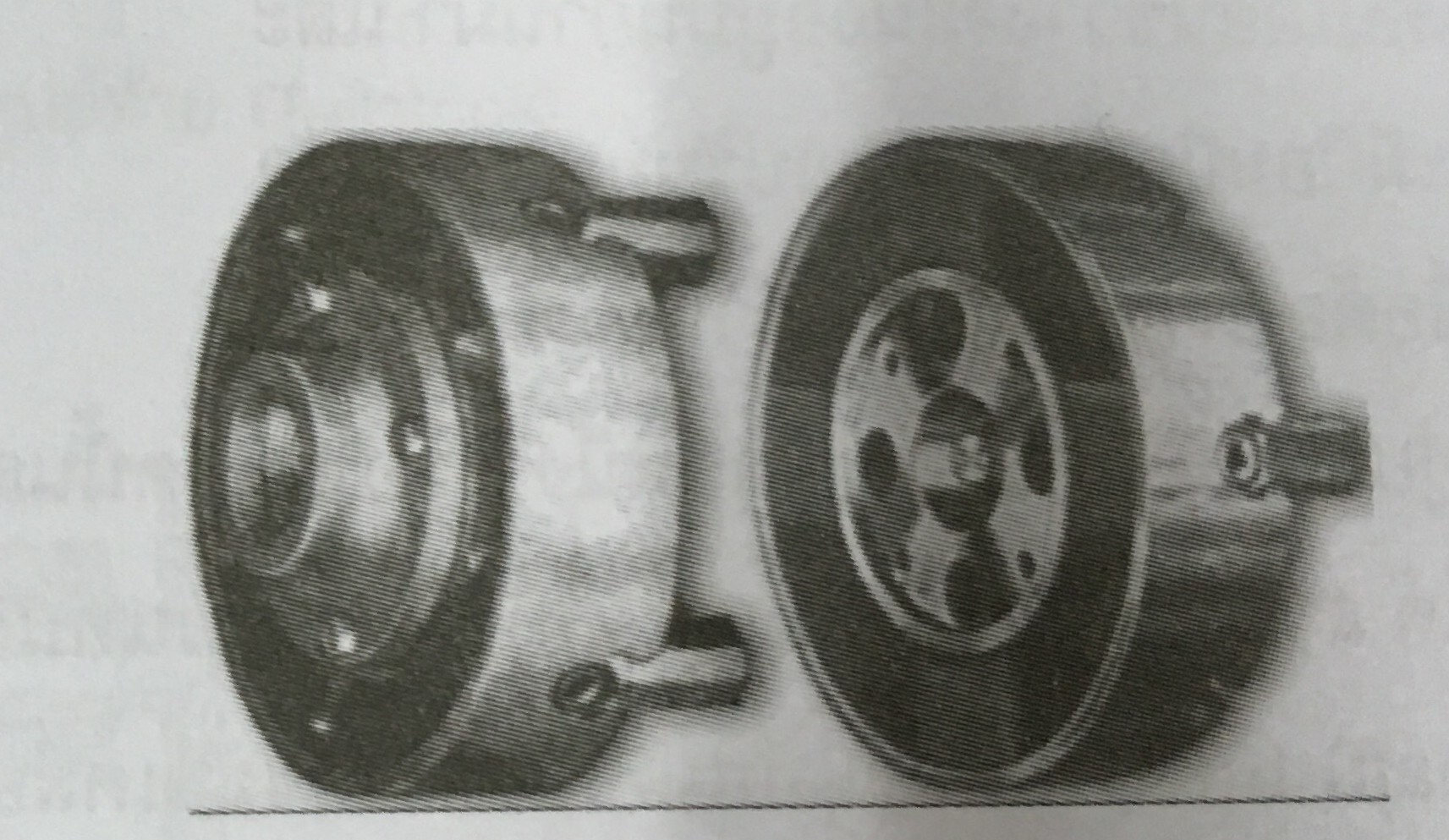

How to put CHUCK in indexing head

The split head is a device that helps clamping to make work with high precision, convenient, fast, able to help the work to be in a stationary manner. The dividing head is commonly used in conjunction with various types of machinery such as drilling machines, lathes, grinding machines, planers and milling machines, etc.

The split head is divided into 2 parts:

1.CHUCK

2.PLATE, which will be screwed onto half platform and mounting plate to prevent the split head from moving back and forth while working.

Working principle of lathe chucks

Chucks hold the workpiece firmly and revolves around itself with the power transmission of the motor and gear set After that, the workpiece is machined with a turning knife moving along the guide rail and the feeding knife is fed transversely to obtain the required dimensions. Most of them are popular for lathe work as follows: lathe stripping, face milling lathe. Turning threads Turning work to reduce the size, turning the shoulder work, drilling holes, boring holes, etc., which the workpieces produced by turning are: mold parts auto parts machine parts, etc.

*Caution when using lathe chucks : Do not hold the chuck wrench on the chuck. because when turning on the lathe The chuck wrench may bounce off the body.

The method of external and internal clamping of the lathe chuck.

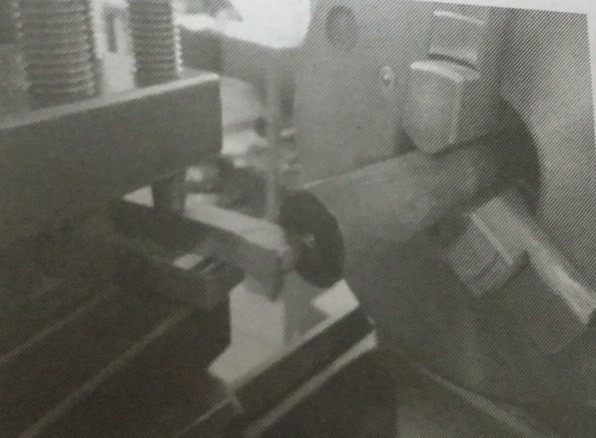

Because the machined workpiece has many shapes. Both square, cylindrical, round, and hexagonal shapes make different holding methods for turning work. for the teeth of the chuck Can be divided into 2 types as follows:

1. The teeth of the chuck that hold it in Suitable for holding cylindrical, round, hexagonal shapes with solid holes as shown in the picture attached below. and can also catch in Ring-shaped with a diameter of the handle passing through the jaws of about Diameter 1.1" (28 mm.) is called a grip in it.

2.The teeth of the chuck that hold the outside Suitable for gripping large lathe workpieces with a diameter of handle through the jaws approx. Diameter 2.7"(68 mm.)

How to work with a lathe with a chuck Turning work can be done in the following ways:

Face turning, peeling, grooving, shoulder, forming, tapering, threading, drilling, boring, printing, etc.

1. Face turning The method is Hold the workpiece with the lathe chuck approximately 10 mm away from the lathe chuck and set the end of the face milling cutter to the center of the workpiece. After that, start face milling from the center of the workpiece to the outer edge of the workpiece.

2. Stripping and turning dimensions The method is Hold the workpiece with a lathe chuck and turn it to the center. For long pieces, drill the center hole first. And set the stripping knife to the center by the angle of the knife edge at an angle of about 10-20 degrees, then draw a small groove according to the desired length on the workpiece with a vernier high gauge. Once the stripping length is approximately 3 mm, check the accuracy with a vernier caliper. After that, the work surface is turned to be smooth, leaving 0.5 mm in size first for the size to grow. length will be correct

3. Turning the shoulder grooving There is a method Hold the workpiece with a lathe chuck and turn it to the center. For long-formed workpieces, lean the center with the center set at the end of the platform. After that, hold the lathe knife to center the shoulder grooving to the center of the workpiece and start grooving the shoulder grooving according to the size specified in the desired work pattern.

4.Curve grooving by the way is Hold the workpiece with the lathe chuck and turn it to the center. For long-formed workpieces, lean the center with the center set at the end of the platform. Center the grooving knife and measure the grooving position. Adjust the low speed and move the grooving knife to the turning position. After that, turn the machine according to the specified design.

5. Turning work forming the curve over there. by the way is Hold the workpiece with the lathe chuck and turn it to the center. And lean the center with the center set at the end of the platform. After that, crimp the lathe knife to the center of the workpiece. Move the knife to the profiling and profiling position according to the specified work order.

6. Turning the tapered turning by the way is Hold the workpiece with a lathe chuck and align it with the pedestal center unit. Set the turning knife centered on the workpiece and set a tapered angle on the top slider. Then tapered to the desired size according to the drawings.

7. Centering hole turning by the way is Hold the workpiece with a lathe chuck and protrude about 10 mm from the jaw, then hold the center drill bit on the drill chuck. Move the center drill closer to the workpiece and drill the center hole to the specified depth.

Image credit https://www.youtube.com/punching by using the center lathe

If you have any question about Lathe Chucks. Please contact us TEL: 099-3535-719

ID LINE : BOWMAP1 Website : http://www.bowmap.com/th