- Category : 4.Carbide -Plate Carbide

- Brand : CHUOKU

- Product Code : -

It is considered a high strength and wear resistant material. Therefore it is commonly used in mold work. Cutting various forms or even in the industry, plastics, ceramics, where the characteristics of carbide sheets will vary according to the nature of work. The reason why the carbide plate It is hard and resistant to staining because Carbide is made of steel, which currently exists in several types as follows.

1.PIG IRON is a metal obtained by smelting iron ore and using an air blast furnace to make pig iron. It contains approximately 95% iron, 3-4% carbon and 1% silicon.

2.MILD STEEL is a metal that contains components. finely slag 1.3% and carbon less than 0.15%, which will look rougher than other metals.

3.CAST IRON is a metal that contains a lot of carbon and can be formed through melting. and after that it is cut, planed, machined and drilled according to usage.

4.STEEL is a metal composed of minerals, carbon iron, manganese, silicon, thus making it stronger and more flexible than other types.

Welding of carbide plates There are 5 types of welds:

1. Carbide plate butt welded joints

2. Carbide plates welded overlapping joints.

3. Carbide plate welded T-shaped joint.

4.Carbide plate welded joints at corners.

5.Carbide plate welded to edge-to-edge joints.

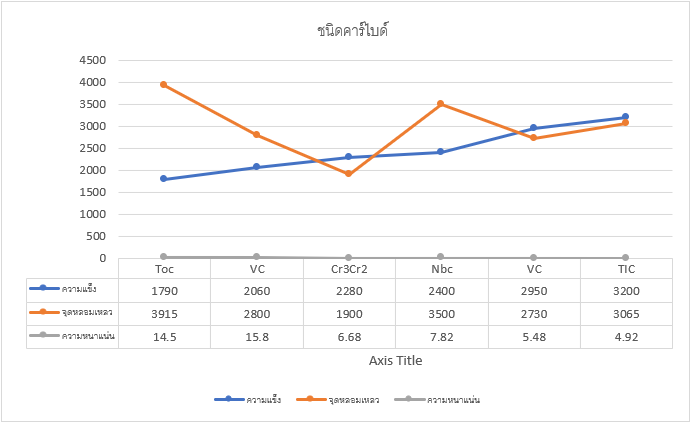

Summary diagram of the properties of carbide types

Carbide type, hardness, melting point, density

Toc 1790 3915 14.5

VC 2060 2800 15.8

Cr3Cr2 2280 1900 6.68

Nbc 2400 3500 7.82

VC 2950 2730 5.48

TIC 3200 3065 4.92

Based on the article Dr. Surasit Rojanan

For more informayion,02-744-3871-5 ext 102-105 FAX 02-748-5058

ID LINE : @BOWMAP Website : http://www.bowmap.com/th