- Category : 3.Cutting / grinding / shaping

- Brand : CHUOKU

- Product Code : CHUOKU (โชกุ)

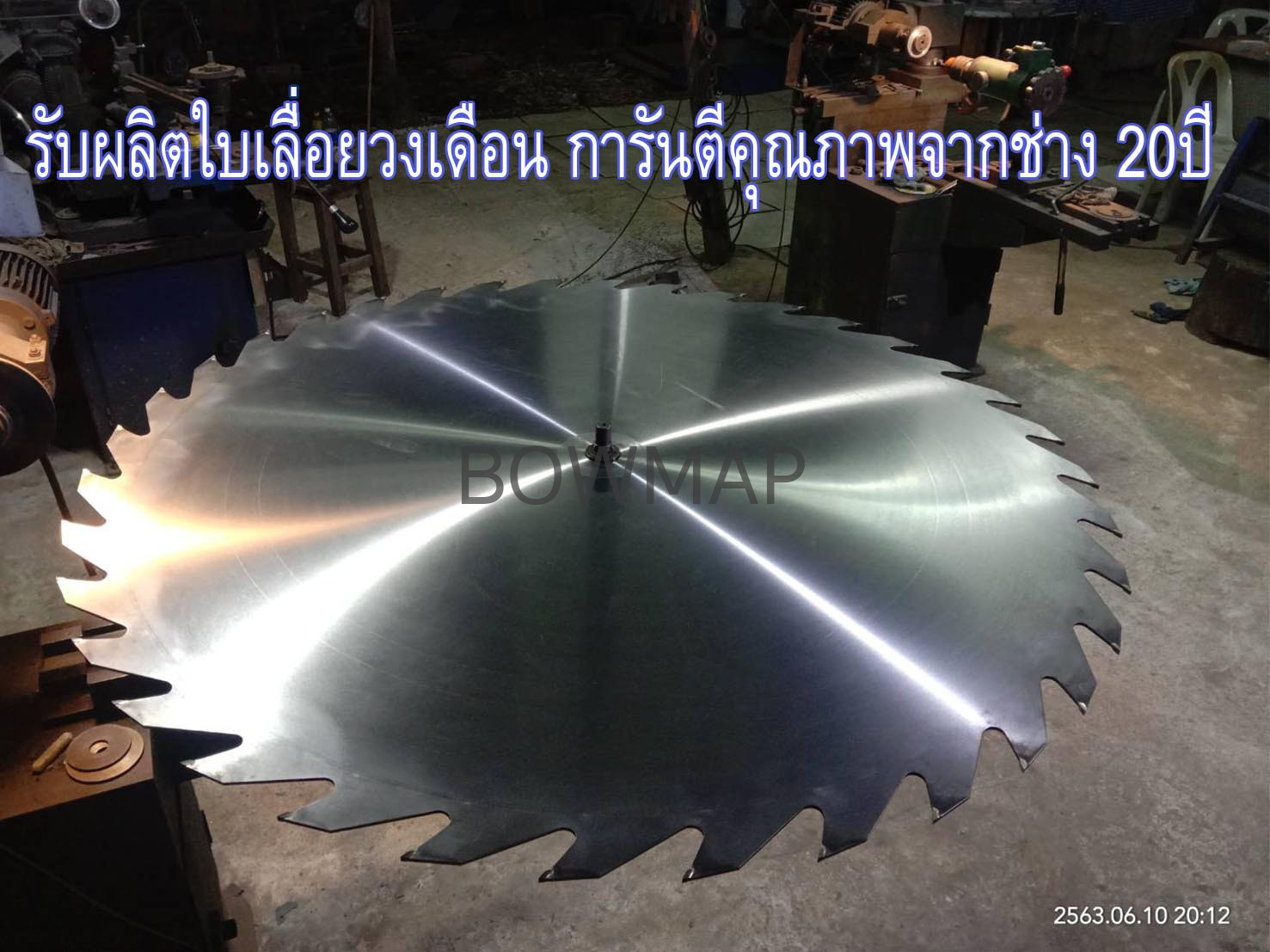

Made to order ice cutting saw blades of all sizes.

Made to order, circular saw blades / reaming steel plates, factory price*

Basic overview ofIce cutting saw blades

Circular saw blades can cut many types of work, such as ice cutting blades. saw blade Plastic and metal cutting saw blades This must have blades or teeth on the edge of the circular saw blade and a motor that allows the circular saw blade to rotate at high speed, allowing the teeth to cut smoothly through the workpiece material.

The factor for choosing the type of circular saw blade is to look at the purpose of what work you choose to cut. and to maintain the circular saw for a long time The choice of motor is also important. Because a good motor will help the blade have the highest speed, able to cut hard materials without breaking or wearing out the blade teeth.

Blade type on circular saw blades

1. Rip saw blade have large and straight teeth so that when cutting work materials can be cut in the same direction as smooth, clean and safe as the main Because there is a vent to remove dust from the cutting and remove it effectively.

2.The combination saw is designed to cut both tear marks and cut marks. And is the most common type of circular saw. Unless you have two circular saw blades at all times. Therefore, the integrated blade allows cutting in both directions. Combined blades come with a variable number of teeth. the more number of teeth The cut will be smoother.

3. The cross saw blade is designed to achieve smooth cuts perpendicular to the material. Because the cross blade has jagged teeth and the teeth alternate from leaning to the left and leaning to the right.

1.Method for calculating the speed of the follower pulley and belt length.

2.How to calculate belt length.

Iron is a hard metal that is steel. Iron is classified as steel (Steels) and iron is classified as cast iron (Cast Irons), which each type of iron has different properties, so the technician should have the knowledge to choose the correct iron.

Which is divided into steel :

1.Carbon steel It is the most commonly used steel. Because it is carbon steel, it is mainly composed of iron and percentage of carbon. The low carbon steel is suitable for production. Auto parts, car bodies, etc. For medium carbon steel, It is used in construction tools. Agricultural tools such as pipes, shafts, screws, etc.

2. Cast iron is steel that uses iron to cast the workpiece. because it has the advantage that cheaper than steel It has a low melting point for easy casting. It also has good flow of liquid metal. Most popular gray cast iron Come to cast a type of workpiece. Large motor frames, pistons, etc. for white cast iron are very hard and brittle. Therefore popular in the production of various types of plumbing joints, car parts, pickup trucks, etc.

3. Stainless steel is a type of alloy steel that is corrosion resistant but does not conduct heat well. Therefore, it is popular to be lined the bottom of the pot with copper or aluminum that conduct heat well. but the price will be more expensive Stainless steel cannot be annealed. but will have some hardness from ironing Therefore, it is popularly used in the production of steak knives for stainless steel. It is popular to make kitchen utensils such as spoons, forks, water bowls, gas stoves, etc. Stainless steel is popular to make furniture that requires steel, etc. because it is cheap.

4. Alloy steel is carbon steel that is specially mixed with other elements. in order to obtain the desired properties of steel, such as making it stronger corrosion resistant Can be used in high temperatures, etc. However, the hardened steel loses its hardness when exposed to high temperatures while working, such as drill bits, etc.

For more information, 02-744-3871-5 ext.102-105 FAX 02-748-5058

ID LINE : @BOWMAP Website : http://www.bowmap.com/th